Rigid to Flexible Conversions

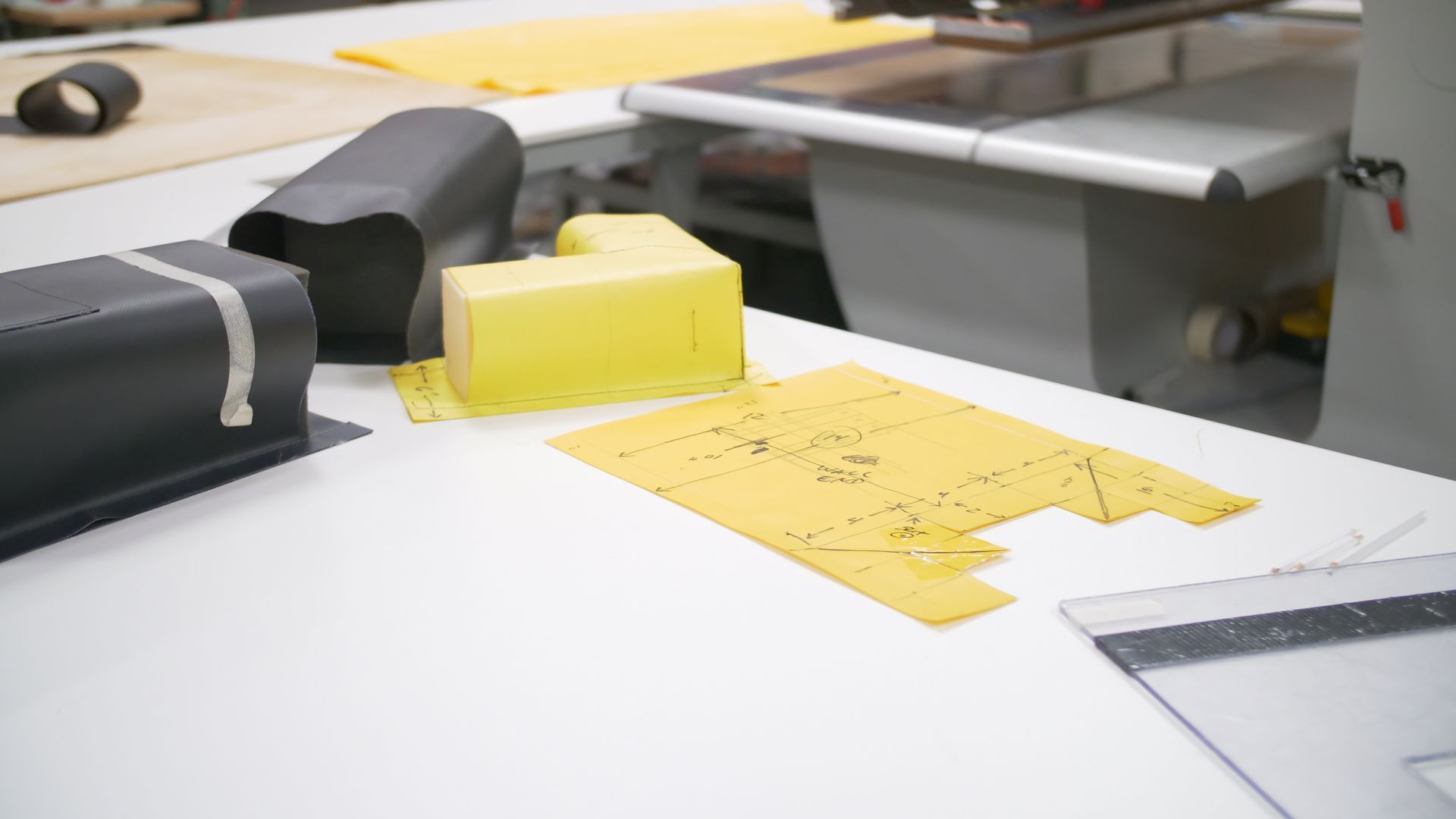

What is a Rigid to Flexible Conversion?

Rigid to flexible conversions involve utilizing flexible vinyls or other technical fabrics as a cost-effective and practical solution for many products currently made from aluminum, steel, or rigid plastics. This process of converting from rigid to flexible materials is a strategic approach that can offer a range of benefits, such as increased efficiency, reduced weight, and easier transport.

A prime example of this is the HVAC ductwork industry. Traditionally, steel has been the preferred material used for HVAC ductwork. However, steel is heavy and can be cumbersome to transport and install. By contrast, vinyl ductwork is becoming increasingly popular due to its lightweight and flexible nature. This alternative material allows for easier installation and a smaller shipping volume, ultimately resulting in reduced costs and enhanced sustainability.

The process of converting from rigid to flexible materials can involve significant design changes to ensure that the flexible materials meet the required performance specifications. However, with the assistance of experienced professionals and advanced technology, the conversion process can yield a final product that is both high-quality and cost-effective.

Your business may benefit from rigid to flexible conversions in multiple ways. For example, materials will have reduced weight, resulting in lower shipping fees. Other benefits include:

○ Reduced manufacturing costs

○ Decreased space usage

○ Improved versatility

Common Applications

Replacing rigid steel, aluminum, or plastic with heat-sealed or sewn vinyl industrial fabrics, such as those commonly used for tarpaulins, can offer numerous advantages. These benefits include reduced weight, increased flexibility, and simplified transportation. Below are several examples of products that could potentially benefit from such a material substitution:

Storage containers and bins:

Vinyl fabric can create collapsible, lightweight storage containers that are easy to transport and can be conveniently folded when not in use.

Temporary shelters and tents:

Temporary shelters, tents, or canopies for outdoor events, disaster relief, or military use can be constructed using vinyl fabric.

Weather-resistant covers:

Flexible materials are an ideal choice for creating weather-resistant covers for machinery, vehicles, and outdoor furniture.

Portable greenhouses:

Constructing lightweight and portable greenhouses using vinyl fabric is an excellent way to offer protection to plants while ensuring ease of assembly and disassembly.

Flexible ductwork:

The use of vinyl fabric enables the creation of flexible ducts that can be employed for ventilation systems in both industrial and commercial settings.

Inflatable structures:

Flexible materials offer a lightweight and highly portable option for creating inflatable event structures, playground equipment, and buildings.

Temporary barriers:

Temporary fencing or barriers for crowd control, construction sites, or for cordoning off hazardous areas can be made using vinyl fabric.

Flexible signage and banners:

Vinyl fabrics are ideally suited for creating flexible signage for advertising or informational purposes because they are durable and cost effective.

Flexible tool organizers:

Using vinyl fabric, it is possible to create tool organizers that are either wall-mounted or freestanding. These organizers offer the convenience of easy reconfiguration based on changing needs.

Gardening containers:

Flexible materials can produce lightweight, portable gardening containers that are easy to store and maintain.

Modular storage cubes:

Lightweight, stackable storage cubes that can be conveniently reconfigured to accommodate different storage needs can be crafted using vinyl fabric.

Partner with carolina covertech today!

At Carolina CoverTech, we specialize in crafting technical fabric product solutions across a variety of industries. With a portfolio of thousands of projects completed, our team is dedicated to delivering solutions that are customized to your specific needs.

For more information about our products and services or to discuss your next project, please contact us today. We are eager to work with you to create a tailored solution that perfectly fits your requirements.

Contact Us Today!

We are ready to answer your questions and get going on your product. Let us know how we can help!

resources

Explore expert insights, industry trends, and actionable advice tailored to help you stay ahead in the competitive landscape. Whether you're an entrepreneur or business owner, we're here to empower your growth and success.

TELL US ABOUT YOUR PROJECT

Share as much or as little as you would like. We have built our business by keeping our word and honoring intellectual property. If you’d rather discuss your concepts over the phone, please give us a call at (800) 763-0243.